Thermal management is a critical aspect of high-performance energy storage systems (ESS), particularly as the demand for efficient and reliable energy solutions continues to rise. High-performance ESS, which includes technologies such as lithium-ion batteries, supercapacitors, and flow batteries, are increasingly utilized in applications ranging from electric vehicles to renewable energy integration. The performance and longevity of these systems are heavily influenced by their thermal conditions.

Effective thermal management ensures that the operating temperature remains within optimal limits, thereby enhancing the overall efficiency and safety of the system. The significance of thermal management can be attributed to several factors. First, temperature fluctuations can lead to performance degradation, where elevated temperatures can accelerate chemical reactions within the battery cells, resulting in reduced capacity and increased internal resistance.

Conversely, low temperatures can hinder the electrochemical processes necessary for energy storage and release. Therefore, maintaining a stable thermal environment is essential for maximizing the operational capabilities of high-performance ESS. Moreover, as these systems are often deployed in diverse environments, from extreme heat to frigid conditions, robust thermal management strategies are necessary to ensure consistent performance across varying operational scenarios.

Key Takeaways

- Thermal management is crucial for high-performance ESS to ensure optimal performance, longevity, safety, and energy efficiency.

- Liquid cooling systems offer advantages such as higher heat transfer efficiency and uniform temperature distribution in ESS.

- Effective thermal management can significantly impact the longevity of cells in high-performance ESS, reducing degradation and extending lifespan.

- Thermal management plays a key role in preventing thermal runaway and ensuring the reliability and durability of high-performance ESS.

- Integrating thermal management into ESS design and manufacturing is essential for maximizing energy efficiency and addressing the challenges of heat dissipation.

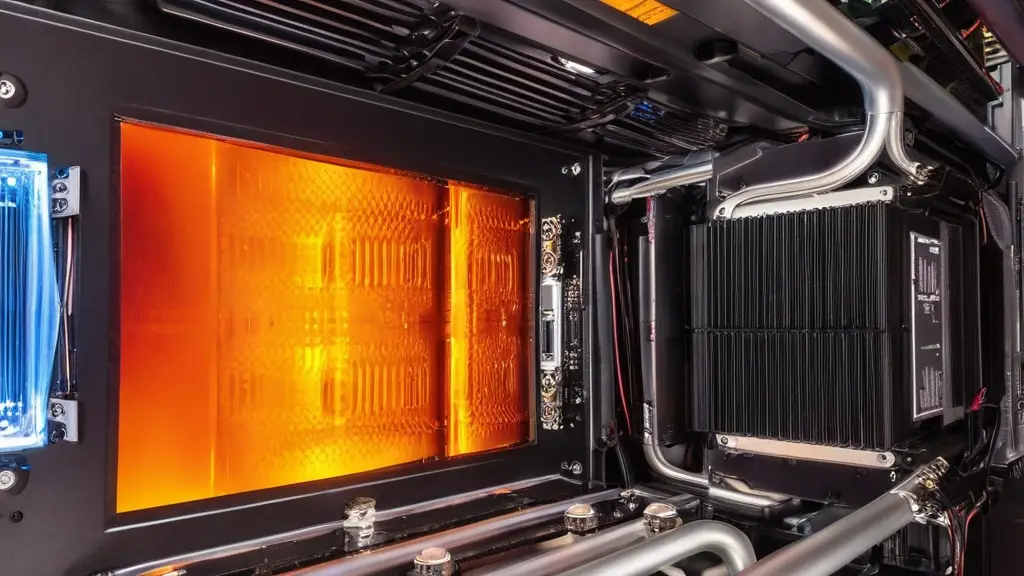

The Advantages of Liquid Cooling Systems for Thermal Management in ESS

Liquid cooling systems have emerged as a preferred solution for thermal management in high-performance ESS due to their superior heat dissipation capabilities compared to traditional air cooling methods. One of the primary advantages of liquid cooling is its ability to maintain uniform temperature distribution across battery cells. This uniformity is crucial because temperature gradients can lead to uneven aging of cells, which ultimately affects the overall performance and lifespan of the battery pack.

By utilizing a liquid medium, heat can be effectively transferred away from hot spots, ensuring that all cells operate within their optimal temperature range. Additionally, liquid cooling systems can be designed to be more compact than air cooling solutions. This compactness is particularly beneficial in applications where space is at a premium, such as in electric vehicles or portable energy storage devices.

The higher thermal conductivity of liquids allows for smaller heat exchangers and cooling channels, which can lead to lighter and more efficient designs. Furthermore, liquid cooling systems can be integrated with other thermal management technologies, such as phase change materials or thermoelectric devices, to enhance their effectiveness further. This integration allows for a more holistic approach to thermal management, addressing both immediate cooling needs and long-term temperature stability.

The Impact of Thermal Management on Cell Longevity in High-Performance ESS

The longevity of battery cells in high-performance ESS is significantly influenced by effective thermal management practices. Elevated temperatures can accelerate degradation mechanisms such as electrolyte decomposition and lithium plating, which can lead to capacity loss and reduced cycle life. For instance, studies have shown that lithium-ion batteries operating at temperatures above 40°C can experience a reduction in lifespan by as much as 50% compared to those maintained at optimal temperatures around 25°This stark contrast underscores the necessity of implementing robust thermal management strategies to prolong cell life.

Moreover, maintaining an optimal thermal environment not only enhances longevity but also improves the overall reliability of the energy storage system. When cells are subjected to extreme temperatures, they may exhibit increased self-discharge rates and diminished performance during charge and discharge cycles. By employing effective cooling techniques, such as liquid cooling or advanced air circulation systems, operators can mitigate these risks and ensure that cells remain within their ideal operating conditions.

This proactive approach not only extends the life of individual cells but also contributes to the overall sustainability of the energy storage system by reducing the frequency of replacements and minimizing waste.

The Role of Thermal Management in Ensuring Optimal Performance of ESS

Optimal performance in high-performance ESS is intrinsically linked to effective thermal management strategies. The efficiency of energy conversion processes within batteries is highly sensitive to temperature variations. For example, at elevated temperatures, the internal resistance of battery cells may decrease, leading to improved charge and discharge rates; however, this benefit is often offset by accelerated degradation processes that compromise long-term performance.

Conversely, low temperatures can result in sluggish electrochemical reactions, reducing the power output and efficiency of the system. Thermal management systems play a pivotal role in balancing these competing factors by ensuring that batteries operate within a narrow temperature range that maximizes performance while minimizing degradation risks. Advanced thermal management solutions can include active cooling systems that adjust based on real-time temperature readings or passive systems that utilize materials with high thermal conductivity to distribute heat evenly across the battery pack.

By optimizing thermal conditions, operators can achieve higher energy densities and improved cycle efficiencies, ultimately leading to enhanced overall system performance.

The Challenges of Thermal Management in High-Performance ESS

Despite the advancements in thermal management technologies, several challenges persist in effectively managing heat within high-performance ESS. One significant challenge is the increasing energy density of modern battery technologies. As manufacturers strive to create batteries with higher energy capacities in smaller form factors, the heat generated during operation becomes more concentrated.

This concentration necessitates more sophisticated cooling solutions that can efficiently dissipate heat without adding excessive weight or complexity to the system. Another challenge lies in the integration of thermal management systems with existing ESS designs. Many high-performance energy storage systems are retrofitted with cooling solutions that may not be optimized for their specific configurations or operational profiles.

This misalignment can lead to inefficiencies and inadequate thermal regulation. Additionally, as energy storage systems become more interconnected with smart grid technologies and renewable energy sources, the dynamic nature of these interactions introduces further complexities in predicting thermal behavior under varying load conditions.

The Relationship Between Thermal Management and Safety in ESS

Safety is a paramount concern in the design and operation of high-performance ESS, and effective thermal management plays a crucial role in mitigating risks associated with overheating and thermal runaway. Thermal runaway is a condition where an increase in temperature leads to further increases in temperature through exothermic reactions within the battery cells. This phenomenon can result in catastrophic failures, including fires or explosions, making it imperative for operators to implement robust thermal management strategies.

By maintaining optimal operating temperatures through effective cooling solutions, operators can significantly reduce the likelihood of thermal runaway events. For instance, advanced monitoring systems that track temperature fluctuations in real-time can trigger cooling mechanisms before critical thresholds are reached. Additionally, incorporating safety features such as thermal fuses or venting mechanisms into battery designs can provide an added layer of protection against overheating scenarios.

These proactive measures not only enhance safety but also instill confidence among users and stakeholders regarding the reliability of high-performance ESS.

The Future of Thermal Management in High-Performance ESS

The future of thermal management in high-performance ESS is poised for significant advancements driven by ongoing research and technological innovations. One promising area of development is the integration of artificial intelligence (AI) and machine learning algorithms into thermal management systems. These technologies can analyze vast amounts of data from battery operations to predict thermal behavior under various conditions, allowing for more precise control over cooling mechanisms and enhancing overall system efficiency.

Moreover, emerging materials such as graphene and advanced phase change materials (PCMs) are being explored for their potential to revolutionize thermal management strategies. Graphene’s exceptional thermal conductivity could enable more efficient heat dissipation, while PCMs can absorb excess heat during peak loads and release it when temperatures drop, providing a passive means of temperature regulation. As these materials become more commercially viable, they could lead to lighter and more efficient thermal management solutions that further enhance the performance and safety of high-performance ESS.

The Integration of Thermal Management into ESS Design and Manufacturing

Integrating thermal management into the design and manufacturing processes of high-performance ESS is essential for achieving optimal performance and longevity. This integration begins at the conceptual stage when engineers must consider how thermal dynamics will influence battery architecture and materials selection. For instance, designing battery packs with built-in cooling channels or utilizing thermally conductive materials can facilitate better heat dissipation from the outset.

Furthermore, manufacturing processes must also adapt to incorporate these thermal management features seamlessly. This may involve developing new assembly techniques that ensure proper alignment of cooling components or utilizing advanced manufacturing methods such as 3D printing to create complex geometries that enhance thermal performance. By embedding thermal management considerations into every stage of design and production, manufacturers can create more efficient and reliable energy storage systems that meet the demands of modern applications.

The Role of Thermal Management in Maximizing Energy Efficiency in ESS

Maximizing energy efficiency is a primary goal for high-performance ESS, and effective thermal management plays a pivotal role in achieving this objective. Energy losses due to heat generation during charge and discharge cycles can significantly impact overall system efficiency. By implementing advanced cooling solutions that maintain optimal operating temperatures, operators can minimize these losses and enhance the overall energy conversion efficiency of the system.

For example, studies have shown that maintaining lithium-ion batteries at optimal temperatures can improve their round-trip efficiency—defined as the ratio of energy output to energy input—by up to 10%. This improvement translates into longer operational times between charges and reduced energy costs over the system’s lifespan. Additionally, efficient thermal management allows for faster charging rates without compromising safety or longevity, further enhancing the usability and appeal of high-performance ESS across various applications.

The Importance of Thermal Management in Preventing Thermal Runaway in ESS

Preventing thermal runaway is one of the most critical aspects of ensuring safety in high-performance ESS, making effective thermal management indispensable. Thermal runaway occurs when a battery cell’s temperature rises uncontrollably due to internal short circuits or external heat sources, leading to rapid degradation and potential failure. Implementing robust cooling strategies is essential for mitigating this risk by ensuring that cells remain within safe operating temperatures throughout their lifecycle.

Advanced monitoring systems equipped with temperature sensors can provide real-time data on cell temperatures, allowing operators to respond proactively if temperatures begin to rise beyond acceptable limits. Additionally, integrating passive safety features such as heat sinks or phase change materials into battery designs can help absorb excess heat before it leads to catastrophic failure. By prioritizing effective thermal management practices, manufacturers can significantly reduce the likelihood of thermal runaway incidents while enhancing user confidence in high-performance ESS.

The Role of Thermal Management in Ensuring Reliability and Durability of High-Performance ESS

Reliability and durability are paramount considerations for high-performance ESS, particularly as these systems are increasingly deployed in critical applications such as grid storage and electric vehicles. Effective thermal management directly influences these attributes by ensuring that battery cells operate within their optimal temperature ranges throughout their lifecycle. Consistent temperature regulation minimizes wear on internal components and reduces the likelihood of premature failure due to overheating or excessive cycling.

Moreover, integrating advanced thermal management solutions into ESS design not only enhances reliability but also contributes to overall system durability by extending operational lifespans. For instance, implementing active cooling systems that adjust based on real-time data allows for dynamic responses to changing environmental conditions or load demands. This adaptability ensures that batteries remain resilient under varying operational scenarios while maintaining peak performance levels over time.

As a result, effective thermal management becomes a cornerstone for achieving long-lasting reliability in high-performance energy storage systems.

FAQs

What is thermal management in the context of high-performance ESS?

Thermal management in the context of high-performance ESS (Energy Storage Systems) refers to the techniques and technologies used to control and maintain the temperature of the system components within an optimal range. This is crucial for ensuring the safety, efficiency, and longevity of the ESS.

Why is thermal management important in high-performance ESS?

Thermal management is important in high-performance ESS because it directly impacts the performance, safety, and lifespan of the system. Proper thermal management helps to prevent overheating, thermal runaway, and degradation of the system components, thereby ensuring reliable and efficient operation.

What are the common thermal management techniques used in high-performance ESS?

Common thermal management techniques used in high-performance ESS include active cooling (such as liquid cooling or air cooling), passive cooling (such as heat sinks or phase change materials), thermal insulation, temperature monitoring and control systems, and thermal modeling and simulation.

How does thermal management impact the efficiency of high-performance ESS?

Effective thermal management helps to maintain the components of the ESS within their optimal operating temperature range, which in turn improves the overall efficiency of the system. By preventing overheating and thermal stress, thermal management ensures that the ESS can deliver and store energy more effectively.

What are the safety implications of inadequate thermal management in high-performance ESS?

Inadequate thermal management in high-performance ESS can lead to safety hazards such as thermal runaway, fire, or explosion. Proper thermal management is essential for preventing these risks and ensuring the safe operation of the ESS, especially in high-demand or high-power applications.